First Principles is committed to design and professional engineering services that provide cost effective solutions to the challenges faced by industry. As a small group of licensed professional engineers, First Principles offers mechanical, electrical, chemical, and process engineering expertise that spans several industries, including automotive, metal stamping, extrusion, injection moulding, chemical conversion, web handling, and machining. This range of experience allows First Principles to introduce a fresh perspective to its clients, which results in unique, successful, client-based solutions.

Business in today’s marketplace is demanding. When the need to grow arises, you can not afford to re-direct your resources to new projects. Your key personnel are involved in running the day to day operations that make your business thrive, and your expertise is required to ensure the continued growth of your business. However, you need some help in managing the next phase of your growth. First Principles is there.

First Principles has successfully managed projects from one small machine to the complete design/build of production facilities. We have worked across North America to manage projects: large, small and everything in between. From project scope to project commissioning, we work closely with the client to understand the requirements, communicate progress, supervise trades, and tabulate costs.

Our dedicated professionals ensure that your project is handled in accordance with your requirements. Our expertise ensures a successful, on-time, on-budget, high quality project.

When your business begins to grow, and you need expertise in managing the project, contact First Principles and allow us to move your company forward.

First Principles has helped several clients in designing, fabricating, commissioning and starting up custom equipment across several industries. We work closely with you to understand your issues, and use our range of expertise across several engineering disciplines to offer custom, client based solutions to your problem.

First Principles can review existing operations and processes to look for opportunities for improvements.

Once we have reviewed your process, we work closely with you to optimize and refine it to maximize returns. Typical reviews often result in cost reduction, cost avoidance, higher yields, or improved throughput as the case may be. Allow us the opportunity to review your process and look for improvements that you may not know you have.

Production environments are demanding. Throughputs and speed are paramount to success. As your business grows, your equipment may not meet the new requirements. You are considering automation to improve throughputs, or new control systems to ensure product quality. You may want to re-arrange the way your existing equipment interacts. You know you need to do something, but are not sure what.

First Principles has a number of years of experience in automating and upgrading existing processes and equipment. We work closely with clients to determine the need, and then offer our expertise in realizing the goal.

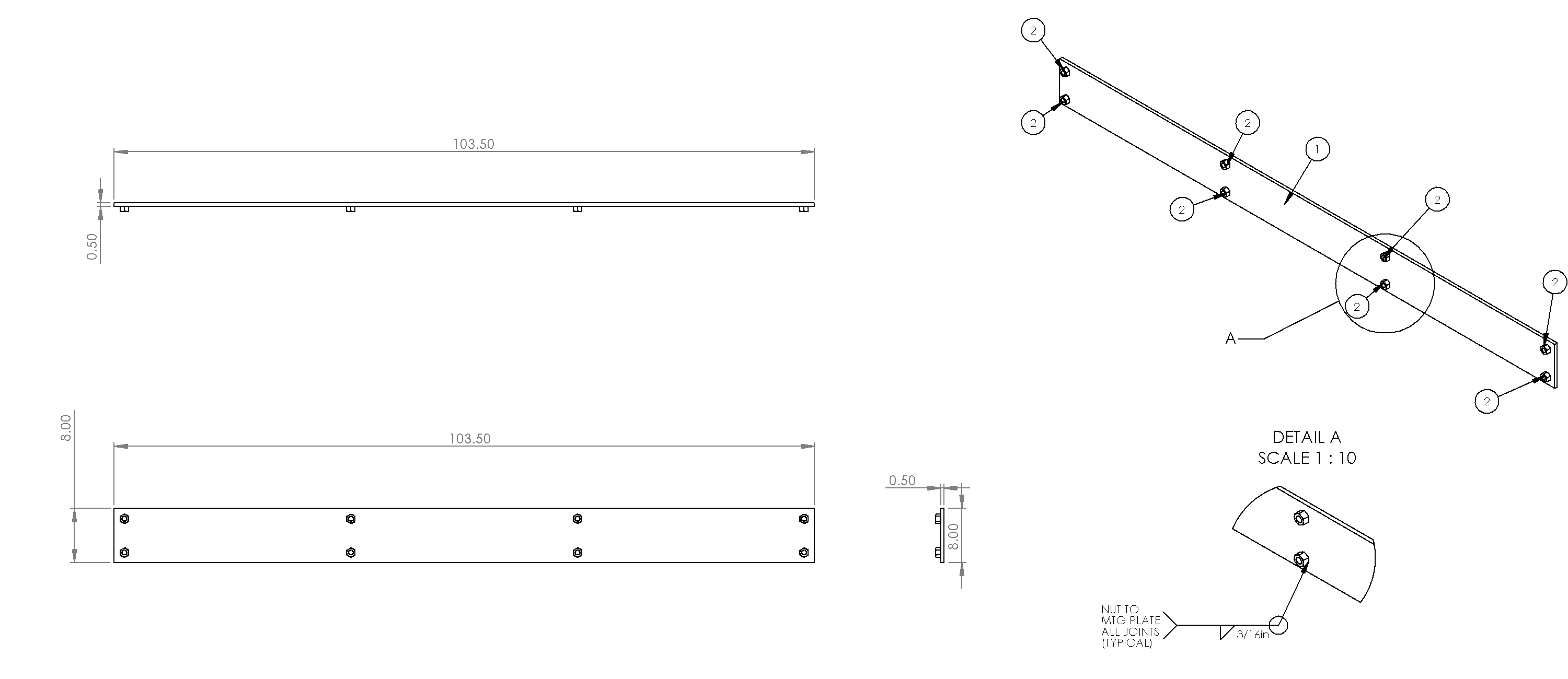

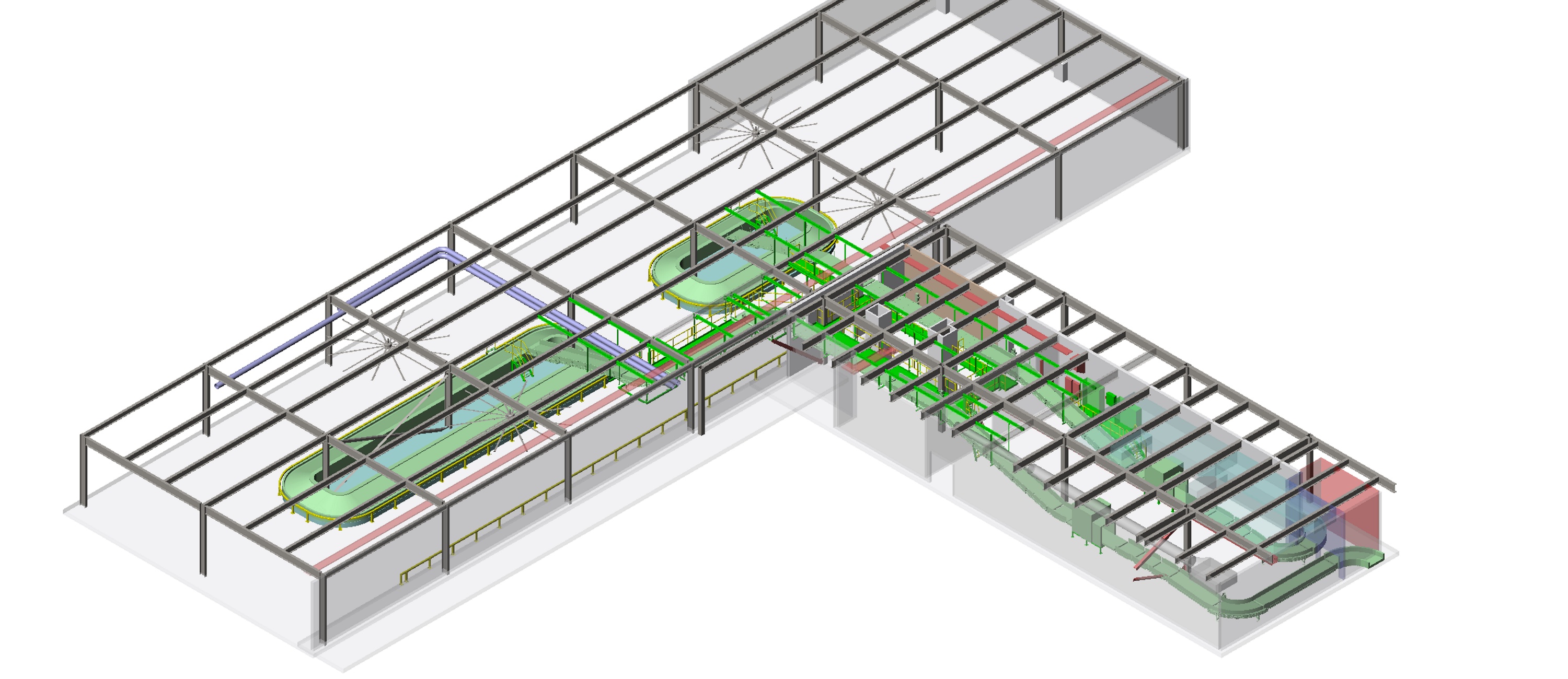

From the smallest details on a single part, complete 3D parametric models of complex assemblies, or plant layouts for construction purposes, First Principles can get your ideas on paper.

We work with the latest software to ensure that your ideas are visualized. A commitment to details ensures that the drawing accurately reflect the design intent. We are committed to working with existing drawing standards (ISO, ANSI) and use GD&T where necessary to ensure clarity and completely convey the design intent.

Whether you need an update to an existing plant layout, extra help with detail drawings, or want to make a 3D presentation of your concepts, allow First Principles to offer you a drafting solution that is tailored to suit your needs.

To help you achieve your goals, our group of professionals holds the highest standard, including:

Registration with Professional Engineers Ontario and its Certificate of Authorization to practice engineering

Familiarity and compliance with codes and standards for design and construction (A.S.M.E., electrical, fire, T.S.S.A., M.O.L., etc)

Use of licensed contractors and reputable suppliers

Ability to work with various cad/cam formats (AutoCAD, Inventor, Solid Works)

Use of project management software to track the progress of each project, with updates supplied to the client as required

FIRST PRINCIPLES, Based in Toronto, Canada

FIRST PRINCIPLES, Based in Toronto, Canada